How are the patterns on the tissue paper created?

- posted by: hds

- No Comments

Sanitary paper, commonly known as “tissue paper,” is primarily used for everyday hygiene purposes. It includes items such as napkins, handkerchiefs, toilet paper, facial tissues, and is a staple in household use. In recent years, the production of sanitary paper has been on a steady rise. Due to varying product performance or quality requirements across different regions, the growth rate varies. However, the supply of high-end products in most markets is expected to continue growing.

Advancements in sanitary paper production equipment, a decrease in the supply of waste paper, and stricter environmental regulations are factors that will drive the development of sanitary paper products towards higher quality and lower production costs.

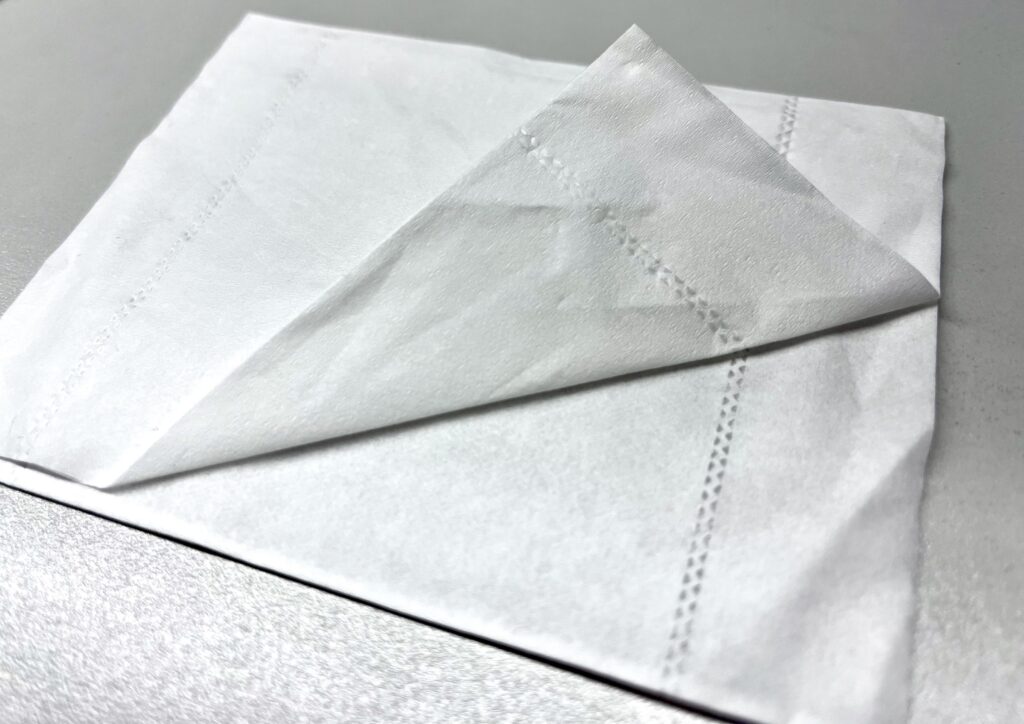

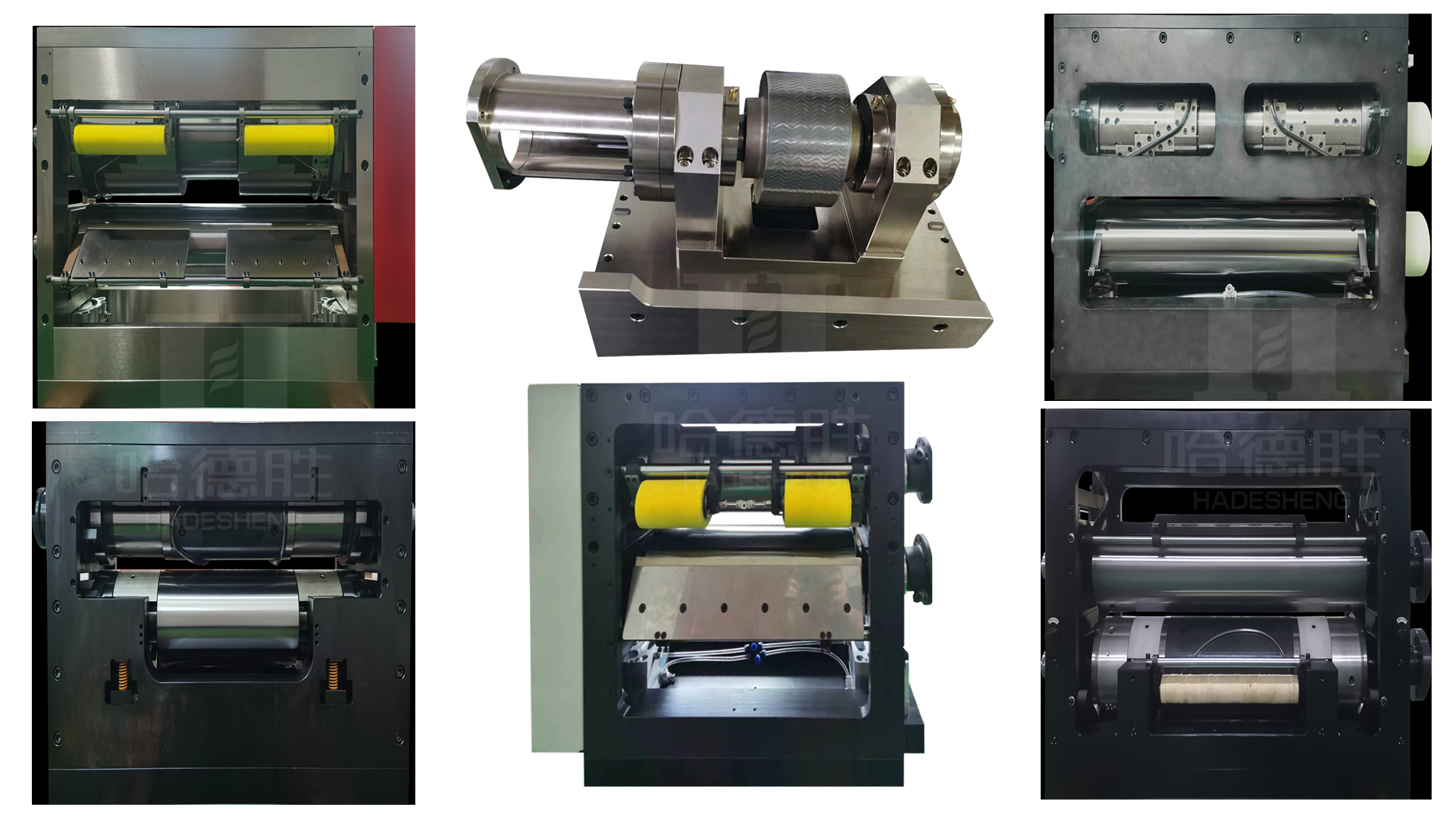

The market offers a wide variety of tissue paper types, with increasingly softer materials. Manufacturers often use mechanical methods to create wrinkles in the paper, enhancing its softness. Today, I will introduce you to the different effects that various embossing patterns on tissue paper can have. There are various types of tissue paper embossing patterns. Generally, major manufacturers imprint their company logos on the embossing patterns. If tissue paper lacks embossing, it can easily separate into layers when used. With embossing, the layers of the tissue paper become tightly bonded and less prone to separation.

Tissue paper embossing can be categorized into two types: full embossing and edge embossing. Full embossing involves patterns in the center and grid-like embossing on the edges, which results in a high degree of tightness. The benefits of embossing include:

1.Enhanced Softness: The embossing on both sides of the tissue paper creates a raised height in the middle, which not only increases the fluffiness of the tissue but also makes it feel softer to the touch.

2.Increased Absorbency: After embossing, the tissue paper forms an uneven surface with small spaces that facilitate the absorption of excess.